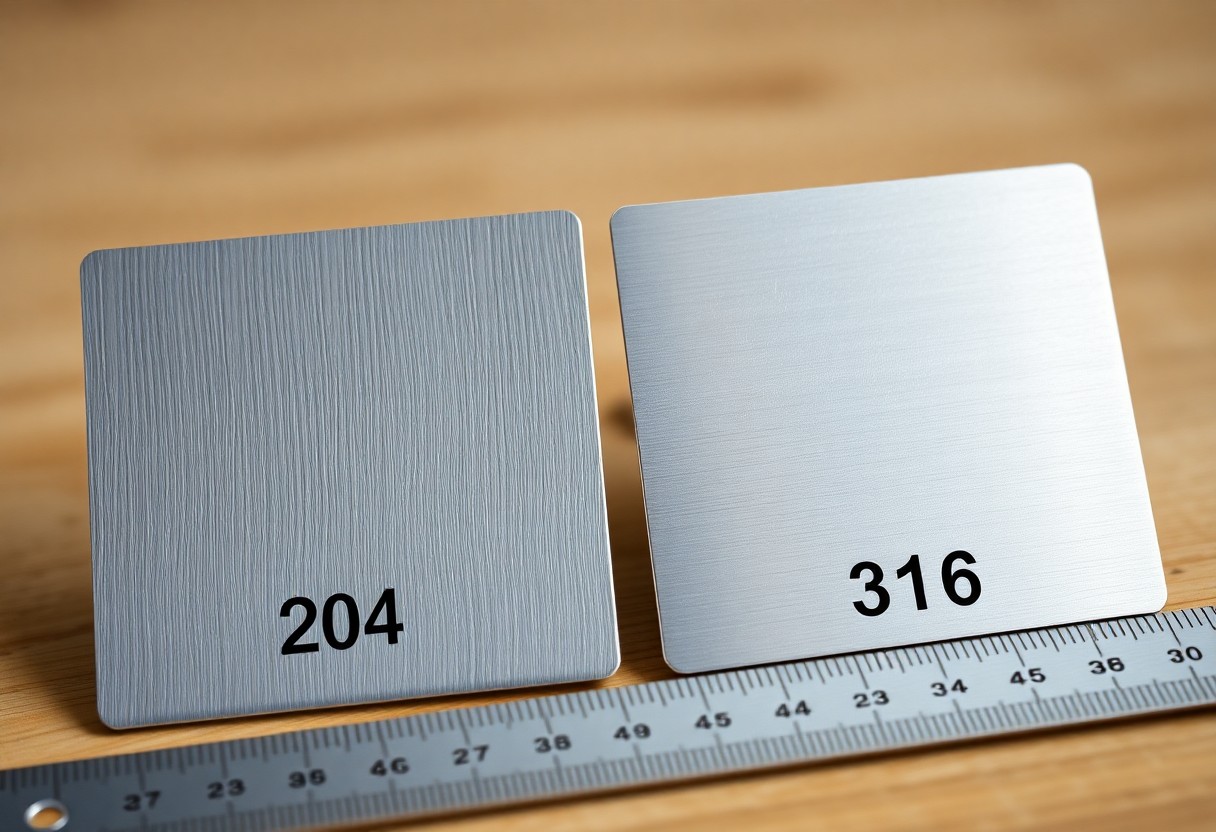

It’s necessary for you to understand the differences between 304 and 316 stainless steel, as each alloy serves distinct purposes based on its composition and properties. While both types are highly corrosion-resistant and durable, 316 stainless steel offers enhanced protection against saline and chloride environments, making it a preferred choice for marine applications. In contrast, 304 stainless steel is versatile and widely used in kitchenware and appliances. This guide will help you make informed decisions on which stainless steel to select for your specific needs.

Key Takeaways:

- 304 stainless steel offers good corrosion resistance and is widely used for general purposes.

- 316 stainless steel contains molybdenum, enhancing its resistance to corrosion, especially in chloride environments.

- Choose 304 for less demanding applications and 316 for harsher environments or marine applications.

Composition of 304 and 316 Stainless Steel

The composition of 304 and 316 stainless steel significantly influences their properties and applications. Both grades belong to the austenitic stainless steel family but differ in specific alloying elements. You’ll find that 304 typically contains 18% chromium and 8% nickel, while 316 includes 16% chromium, 10% nickel, and 2% molybdenum, which enhances its resistance to corrosion, particularly in chloride environments.

Chemical Elements

The unique chemical makeup of 304 and 316 stainless steels dictates their behavior in various environments. While both grades share chromium and nickel, the addition of molybdenum in 316 boosts its resistance to pitting and crevice corrosion, making it an ideal choice for marine applications or chemical processing.

Mechanical Properties

Your choice between 304 and 316 stainless steel also hinges on their mechanical properties. While both exhibit excellent ductility and formability, 316 steel generally offers higher tensile strength and improved toughness at elevated temperatures, making it suitable for more demanding applications.

Further insights reveal that the yield strength of 304 stainless steel is around 215 MPa, whereas 316 offers higher strength ranging from 230 to 250 MPa. This difference can influence your selection depending on the load-bearing requirements of your project. Additionally, these variations in mechanical properties can impact the durability and longevity of components exposed to harsh environments, underscoring the importance of selecting the right grade based on specific performance criteria.

Corrosion Resistance

The corrosion resistance of stainless steel largely hinges on its composition. 316 stainless steel outperforms 304 in environments with high chloride concentrations, such as coastal regions or chemical processes, thanks to its molybdenum content. This makes 316 the preferred choice for marine applications and chemical handling. Conversely, while 304 offers decent resistance, it is more susceptible to pitting and crevice corrosion in harsh conditions.

Environment and Applications

Your choice between 304 and 316 stainless steel should consider the specific environment. 304 is suitable for indoor applications and areas less exposed to corrosive elements, like kitchen appliances and food processing equipment. If you operate in marine settings or handle chemicals, 316 provides enhanced durability and longevity.

Surface Treatments

Surface treatments can significantly impact the performance and aesthetics of stainless steel. Techniques such as passivation, which enhances corrosion resistance, are commonly employed on both 304 and 316 grades. Additionally, polishing and anodizing can improve appearance and create a protective barrier against environmental factors.

Passivation involves treating the stainless steel with acid to remove free iron and enhance the natural oxide layer, thereby increasing corrosion resistance. This process is particularly effective for both 304 and 316 grades, but it’s important to choose the right treatment based on the application to ensure optimal performance and durability. Other surface treatments, like electropolishing, can further enhance the finish and reduce contaminants, especially in industries like pharmaceuticals and food processing, where hygiene is paramount.

Cost Comparison

| Type of Stainless Steel | Average Cost per Pound |

|---|---|

| 304 Stainless Steel | $2.00 – $3.00 |

| 316 Stainless Steel | $2.50 – $4.00 |

Pricing Trends

Currently, the price gap between 304 and 316 stainless steel reflects their differences in composition, demand, and application. While 304 is generally more affordable due to its wider availability, 316 can command a premium price for its enhanced corrosion resistance, particularly in marine and chemical environments. Tracking market fluctuations can help you make informed purchasing decisions.

Value for Money

When assessing value for money, consider both the initial cost and the long-term benefits. 316 stainless steel’s superior resistance to corrosion and pitting makes it a more cost-effective choice in demanding conditions, as it often requires less maintenance and replacement over time.

Investing in 316 stainless steel might seem pricier upfront, but for projects exposed to harsh environments-like coastal areas or chemical processing plants-the durability can lead to significant cost savings. The longevity of materials translates to fewer repairs and replacements, ensuring that the overall lifecycle cost aligns with your budgetary constraints while enhancing performance. Thus, for projects requiring durability and reliability, 316 often provides better value for your investment in the long run.

Applications of 304 Stainless Steel

304 stainless steel is highly versatile and finds extensive use across various industries due to its excellent corrosion resistance and formability. You will commonly see it in kitchen equipment, food processing equipment, and plumbing systems. Its ability to withstand high temperatures and oxidation makes it a preferred choice in industries ranging from construction to automotive parts.

Industry Use Cases

In the food and beverage industry, 304 stainless steel is vital for manufacturing sanitary equipment, storage tanks, and conveyor belts. It also plays a significant role in architectural applications such as rails and facades. In the chemical industry, you’ll find it used in reactors and heat exchangers, where durability and resistance to various chemicals are paramount.

Product Examples

Common products made from 304 stainless steel include sinks, countertops, and kitchen appliances, providing both aesthetic appeal and functionality. Additionally, you’ll see 304 stainless in automotive parts like exhaust systems and trim, delivering both performance and a sleek finish.

For example, kitchen sinks crafted from 304 stainless steel are not only easy to clean but also resist rust and staining, ensuring longevity. In vehicles, 304 stainless steel exhaust systems enhance performance while resisting high temperatures, showing why manufacturers prefer this material. Its adaptability spans everyday items and critical components, proving its role in modern manufacturing and design.

Applications of 316 Stainless Steel

You’ll find 316 stainless steel employed in diverse environments where corrosion resistance is paramount. Industrial settings, marine applications, and food processing are just a few areas benefiting from its robust properties. Its ability to withstand saltwater and harsh chemicals makes it suitable for chemical processing plants and pharmaceutical manufacturing. Additionally, medical devices often utilize 316 due to its biocompatibility and ease of sterilization.

Unique Features for Specific Uses

The unique composition of 316 stainless steel, particularly its molybdenum content, enhances its resistance to pitting and crevice corrosion, especially in chloride environments. This feature is especially advantageous in marine applications and coastal structures, where exposure to seawater is constant. Its durability in acidic environments, such as those found in chemical processing, ensures that you have equipment that lasts longer and maintains integrity.

Product Examples

Common products made from 316 stainless steel include marine hardware, chemical storage tanks, and surgical instruments. For instance, boat fittings and components truly leverage the alloy’s resistance to corrosion from saltwater. Additionally, you will find 316 stainless steel in heat exchangers and pressure vessels, emphasizing its versatility across sectors.

Delving deeper into product examples, items such as 316 stainless steel tubing and valves are vital in the oil and gas industry due to their ability to withstand high pressures and corrosive environments. You’ll see 316 stainless steel used in the manufacturing of equipment like pumps and compressors, which require not only structural integrity but also resistance to wear from abrasive materials. In medical fields, surgical instruments crafted from this alloy not only resist corrosion but are also easy to clean, ensuring optimal hygiene and safety for patients.

Maintenance and Care

To ensure optimal performance and longevity, regular maintenance and care for stainless steel are important. Both 304 and 316 stainless steels require specific practices to maintain their appearance and functionality, especially in demanding environments. You should inspect regularly for signs of corrosion and clean as necessary to preserve the material integrity.

Cleaning Methods

Effective cleaning methods for stainless steel include using mild soap solutions, vinegar, or specialized stainless steel cleaners. Avoid abrasive pads that can scratch the surface. For tough stains, a paste of baking soda and water can be used gently, followed by a thorough rinse to prevent residue buildup. Refrain from using chlorine-based cleaners, as these can lead to pitting corrosion over time.

Longevity Factors

The longevity of stainless steel largely depends on exposure conditions and the quality of maintenance. Environmental factors like humidity, saline exposure, and chemical contact can accelerate deterioration. You’ll want to factor in application specifics to ensure you’re choosing the right grade of stainless steel for your needs.

- Regular inspections are vital for identifying early signs of corrosion.

- Keeping stainless steel dry and clean can significantly increase its lifespan.

- Pitting and crevice corrosion are common in harsh environments; preventive measures are imperative.

- After cleaning, apply a light coat of mineral oil to protect surfaces.

Various underlying factors influence the longevity of stainless steel. The level of alloying elements, such as nickel and molybdenum, plays a significant role in resisting corrosion. For instance, 316’s higher molybdenum content enhances its performance in chloride environments. Additionally, your application environment-such as exposure to saltwater or chemicals-will dictate the necessary care strategies.

- Understanding the specific environmental conditions can guide your choice of cleaning techniques and maintenance schedules.

- Choosing the appropriate grade can minimize future issues, saving costs down the line.

- After applying protective agents, inspect surfaces periodically to ensure maintenance longevity.

To wrap up

Following this comparison, you should have a clearer understanding of the differences between 304 and 316 stainless steel. While 304 is suitable for many applications due to its corrosion resistance and affordability, 316 offers enhanced protection against saltwater and harsh environments, making it ideal for marine and chemical applications. Choosing the right one depends on your specific needs and the environment in which your materials will be used. Assess your requirements carefully to ensure optimal performance and longevity in your projects.

FAQ

Q: What are the main differences between 304 and 316 stainless steel?

A: The primary differences between 304 and 316 stainless steel lie in their composition and resistance to corrosion. 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel includes 16% chromium, 10% nickel, and 2% molybdenum. The addition of molybdenum in 316 enhances its corrosion resistance, especially against chlorides, making it suitable for marine environments.

Q: Which type of stainless steel is better for outdoor applications?

A: For outdoor applications, 316 stainless steel is generally a better choice due to its superior corrosion resistance. This alloy is less susceptible to rust and pitting from exposure to saltwater and harsh weather conditions compared to 304 stainless steel.

Q: Are there differences in cost between 304 and 316 stainless steel?

A: Yes, there is typically a price difference between 304 and 316 stainless steel, with 316 being more expensive due to its enhanced properties and composition. This cost can be a significant factor when choosing the right alloy for a specific application, balancing performance needs against budget constraints.