Over time, selecting the right stainless steel grade for your application can greatly impact durability, particularly when it comes to corrosion resistance. In this post, you will discover the significant differences between 410 and 316 stainless steel, including their respective properties and how they respond to various environments. By understanding these distinctions, you can make informed decisions that enhance the longevity and performance of your products.

Key Takeaways:

- 410 stainless steel offers better hardness and wear resistance, making it suitable for applications where strength is prioritized.

- 316 stainless steel provides superior corrosion resistance, particularly in harsh environments such as marine and chemical applications.

- Choosing between 410 and 316 depends on the specific application requirements, balancing between strength and corrosion resistance.

Overview of Stainless Steel

Stainless steel is an alloy steel containing a minimum of 10.5% chromium, which provides excellent corrosion resistance. This unique combination of elements creates a material with remarkable strength, durability, and versatility, making it ideal for various applications from kitchenware to industrial equipment. Its resistance to staining, rusting, and tarnishing sets it apart from other metals, allowing you to maintain aesthetic quality over time.

Definition and Properties

Stainless steel is defined as a group of iron-based alloys that contain chromium, enhancing their resistance to oxidation and corrosion. It exhibits a range of properties, including high tensile strength, ductility, and ease of fabrication. Additionally, it maintains its mechanical properties at both high and low temperatures, making it suitable for diverse environments and conditions.

Types of Stainless Steel

The primary types of stainless steel are classified into five categories: austenitic, ferritic, martensitic, duplex, and precipitation-hardening. Each type has unique characteristics based on its microstructure, contributing to specific applications in industries like construction, automotive, and healthcare. Understanding the differences allows you to select the most suitable stainless steel for your project needs.

| Austenitic | Highly corrosion-resistant and non-magnetic, typically used in kitchen equipment. |

| Ferritic | Magnetic and less ductile, used in automotive applications and kitchenware. |

| Martensitic | Offers high strength and wear resistance, commonly found in knives and cutting tools. |

| Duplex | Combines properties of ferritic and austenitic steels, providing high strength and corrosion resistance. |

| Precipitation-Hardening | Can achieve high strength with heat treatment, used in aerospace and other high-performance applications. |

Each type of stainless steel serves key roles in multiple sectors. For example, austenitic stainless steel is widely favored for its versatility and ease of welding, often seen in food processing. Ferritic steel is practical in automotive exhaust systems due to its cost-effectiveness. Similarly, martensitic types can be utilized where sharpness is necessary, such as in surgical instruments. Duplex alloys combine high strength with excellent corrosion resistance, ideal for harsh chemical environments. Thou know the type that best fits your requirements.

| Applications | Description |

| Austenitic | Food processing, pharmaceuticals, and building structures. |

| Ferritic | Kitchen utensils and automotive parts. |

| Martensitic | Knives, tools, and turbines. |

| Duplex | Pulp and paper industry, marine applications. |

| Precipitation-Hardening | Aerospace components and high-stress applications. |

- Utilize the characteristics of each type for your specific needs.

- Analyze the properties based on corrosion resistance levels.

- Factor in mechanical properties when selecting stainless steel.

- Consider the environment in which the steel will be used.

- Thou will find that understanding these types enhances your material choice.

Comparison of 410 and 316 Stainless Steel

| Property | 410 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Moderate | Excellent |

| Tensile Strength | High | Moderate |

| Temperature Resistance | Up to 1500°F | Up to 800°F |

Chemical Composition

410 stainless steel primarily consists of chromium, with around 11-13% chromium content, giving it basic corrosion-resisting properties. In contrast, 316 stainless steel contains significant nickel and molybdenum, providing enhanced resistance to corrosion, especially against chlorides. Specifically, it includes about 16% chromium, 10% nickel, and 2% molybdenum, which allows for better performance in harsh environments.

Mechanical Properties

When assessing mechanical properties, 410 stainless steel offers high tensile strength, making it suitable for applications requiring hardness and wear resistance. Conversely, 316 stainless steel, while having lower tensile strength, provides better ductility and toughness, making it more adaptable to harsh conditions.

In practical terms, 410 stainless steel may be preferred in applications like cutlery or kitchen utensils due to its hardiness, while 316 stainless steel excels in marine environments or chemical processing where corrosion resistance is paramount. If you evaluate the specific needs of your project, you’ll find that while both types safeguard against wear, 316’s superior corrosion resistance makes it indispensable for demanding environments.

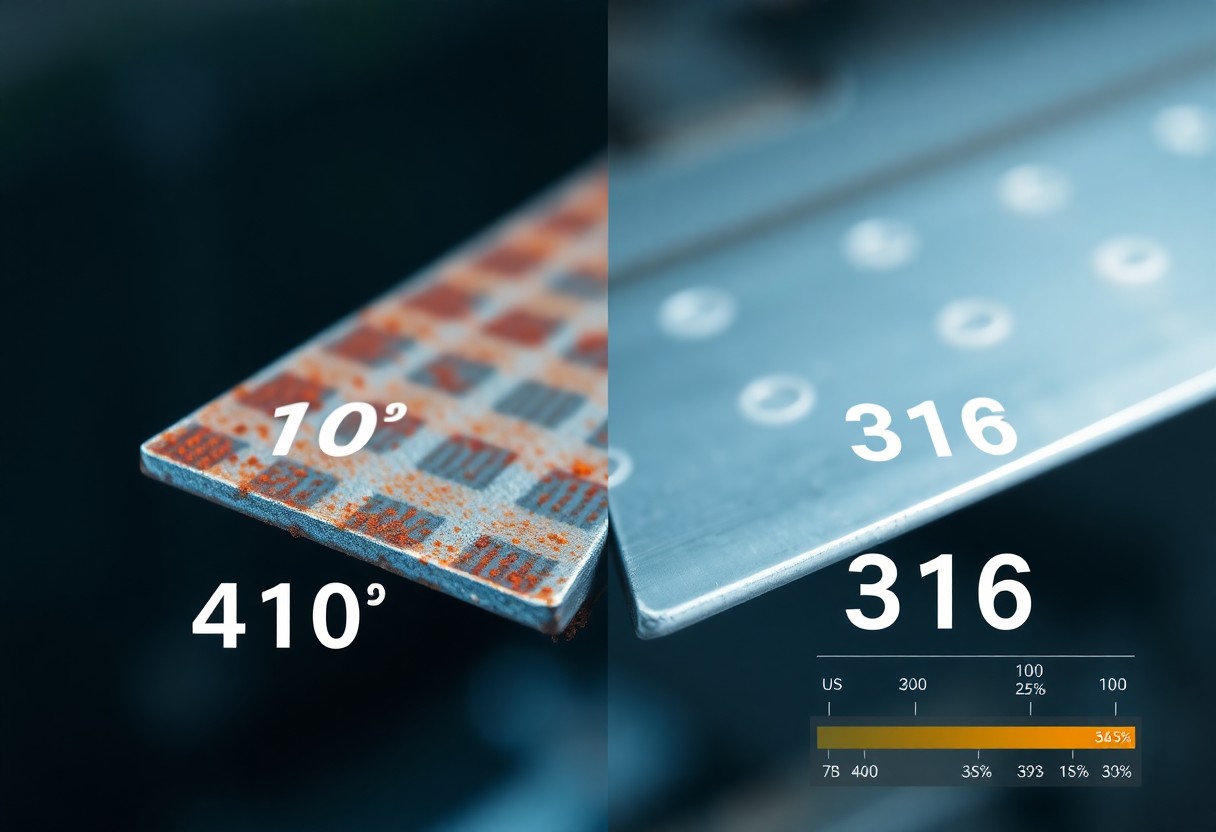

Corrosion Resistance

Corrosion resistance is a primary factor when selecting between 410 and 316 stainless steel, particularly in environments prone to oxidation and pitting. 316 stainless steel, enriched with molybdenum, offers superior resistance against saltwater and chloride exposure, making it ideal for marine and chemical applications. In contrast, 410 stainless steel, while tougher and wear-resistant, lacks the same level of corrosion protection, making it more suited for dry environments or applications where mechanical strength outweighs corrosion concerns.

Factors Affecting Corrosion

Several factors influence the corrosion resistance of stainless steel, including environmental conditions, alloy composition, and surface finish. Understanding these elements can help you choose appropriately based on your specific application needs.

- Environmental exposure

- Alloy elements and composition

- Surface finishing techniques

- Temperature and humidity levels

- Presence of chlorides or aggressive chemicals

After evaluating these factors, the choice between materials becomes informed by the operating environment.

Corrosion Resistance of 410 Stainless Steel

While 410 stainless steel exhibits decent corrosion resistance, its effectiveness diminishes in harsh environments. The chromium content (about 11.5% to 13.5%) provides some level of resistance, but it is not adequate for environments with high moisture or corrosive agents.

The nature of 410 stainless steel means that it can withstand wear and tear well, but its performance in corrosive settings will not meet expectations as effectively as other alloys. Any restoration of corrosion resistance typically occurs only through proper maintenance and finishing, making it less favorable for heavily saline or acidic applications.

Corrosion Resistance of 316 Stainless Steel

On the other hand, 316 stainless steel is designed specifically to combat severe corrosion challenges, thanks to its molybdenum inclusion, which bolsters its resistance against pitting and crevice corrosion. With a chromium content of 16% to 18%, it excels in marine and chemical environments.

316 stainless steel’s advanced corrosion resistance makes it the alloy of choice for applications exposed to salt water or harsh chemicals. This makes it invaluable in the food industry, medical applications, and any setting where hygiene and alloy integrity are paramount, often lasting significantly longer than its 410 counterpart in similar harsh environments.

Applications of 410 and 316 Stainless Steel

Understanding where to apply 410 and 316 stainless steels can enhance the performance of your projects. Each type offers distinct benefits, making them suitable for specific environments and uses. Whether you’re considering automotive components or marine applications, knowing the right steel to select is crucial for durability and effectiveness.

Where to Use 410 Stainless Steel

410 stainless steel is ideal for applications requiring high wear resistance and moderate corrosion resistance. You’ll find it commonly used in cutlery, automotive parts, and industrial equipment like pumps and valves. Its ability to withstand heat treatment allows for tailored hardness, making it a preferred choice for tools and dies.

Where to Use 316 Stainless Steel

For marine environments and chemical processing, 316 stainless steel is your go-to material. Its exceptional resistance to pitting and crevice corrosion makes it suitable for equipment in coastal areas, paper and pulp processing, and food processing industries. Additionally, you often see it in medical devices and pharmaceuticals due to its biocompatibility.

316 stainless steel’s versatility extends to applications that require sanitation and resistance to aggressive chemicals, such as in brewing equipment and marine applications. Its molybdenum content enhances corrosion resistance, ensuring a longer lifespan in harsh environments. This makes it indispensable for structures and components exposed to moisture, saltwater, and other corrosive substances, providing reliability and safety in critical applications.

Cost Considerations

When evaluating the cost implications of 410 and 316 stainless steel, you need to assess both the upfront expenses and potential long-term savings. Your choice can significantly impact your project budget, maintenance costs, and overall performance.

Price Differences

In general, 410 stainless steel tends to be less expensive than 316. You can typically expect to pay around 15-30% less for 410, depending on market fluctuations and supply chains. These differences can influence your material selection process, especially for large-scale projects.

Long-term Value

While 410 stainless steel is cheaper upfront, its long-term value may not match that of 316 stainless steel, especially in corrosive environments. Your choice should reflect potential repair and replacement costs alongside the initial investment, balancing short-term savings with extended durability.

Investing in 316 stainless steel pays off in environments prone to corrosion, like marine applications or chemical processing. For example, you may save on maintenance and replacement costs due to 316’s enhanced resistance to pitting and crevice corrosion. Over a decade or more, these savings can surpass the initial price difference, making 316 a more economical choice in the long run despite the higher upfront cost. Your specific use case and environment will guide this decision best.

Maintenance and Care

To ensure the longevity and performance of stainless steel, routine maintenance and care are crucial. Regular inspections can help identify potential corrosion or damage early on, enabling you to take action before more significant problems arise. Adhering to best practices and using appropriate cleaning methods will significantly enhance the durability of your stainless steel items.

Best Practices for Stainless Steel

You should always use non-abrasive materials for cleaning to avoid scratching the surface. Opt for cleaning products specifically formulated for stainless steel, as these can effectively remove grime without damaging the finish. Make it a habit to dry the surface thoroughly after cleaning to prevent water spots and promote a shiny appearance.

Recommended Cleaning Methods

For routine cleaning, warm soapy water is often sufficient; however, tougher stains might require a specialized cleaner. Employing a microfiber cloth or soft sponge will prevent scratches while applying the cleaner. Always rinse with clean water and dry completely to maintain the integrity of the finish.

Using a mixture of vinegar and water can be particularly effective for light tarnish, ensuring you spray it on and wipe it off in the direction of the grain. For stubborn stains, consider a paste made of baking soda and water, applied gently with a soft cloth. Avoid harsh chemicals or steel wool, which can harm the surface. Regular upkeep using these methods not only enhances appearance but also increases the lifespan of your stainless steel items.

To wrap up

From above, you can see that 410 and 316 stainless steels differ significantly in corrosion resistance. While 316 offers superior protection against harsh environments due to its additional molybdenum content, 410 may be more suitable for applications where strength and wear resistance are prioritized. Depending on your specific needs and environmental conditions, selecting the right grade can enhance the longevity and performance of your materials. Ultimately, understanding these differences helps you make informed choices to ensure the best outcomes for your projects.

FAQ

Q: What are the main differences between 410 and 316 stainless steel in terms of corrosion resistance?

A: 410 stainless steel is primarily a martensitic alloy with lower corrosion resistance, making it suitable for indoor environments. In contrast, 316 stainless steel, an austenitic alloy, contains molybdenum, which significantly enhances its corrosion resistance, especially against chlorides and harsh environments.

Q: In which environments would 410 stainless steel show significant corrosion issues compared to 316 stainless steel?

A: 410 stainless steel can suffer from pitting and stress-corrosion cracking in chloride-rich environments, such as coastal areas or industrial settings. Conversely, 316 stainless steel is designed for marine applications and other corrosive environments, effectively mitigating these issues.

Q: Can the corrosion resistance of 410 stainless steel be improved?

A: Yes, the corrosion resistance of 410 stainless steel can be enhanced through surface treatments such as passivation, coating, or applying a layer of a more corrosion-resistant alloy. However, it will still not match the inherent corrosion resistance of 316 stainless steel.