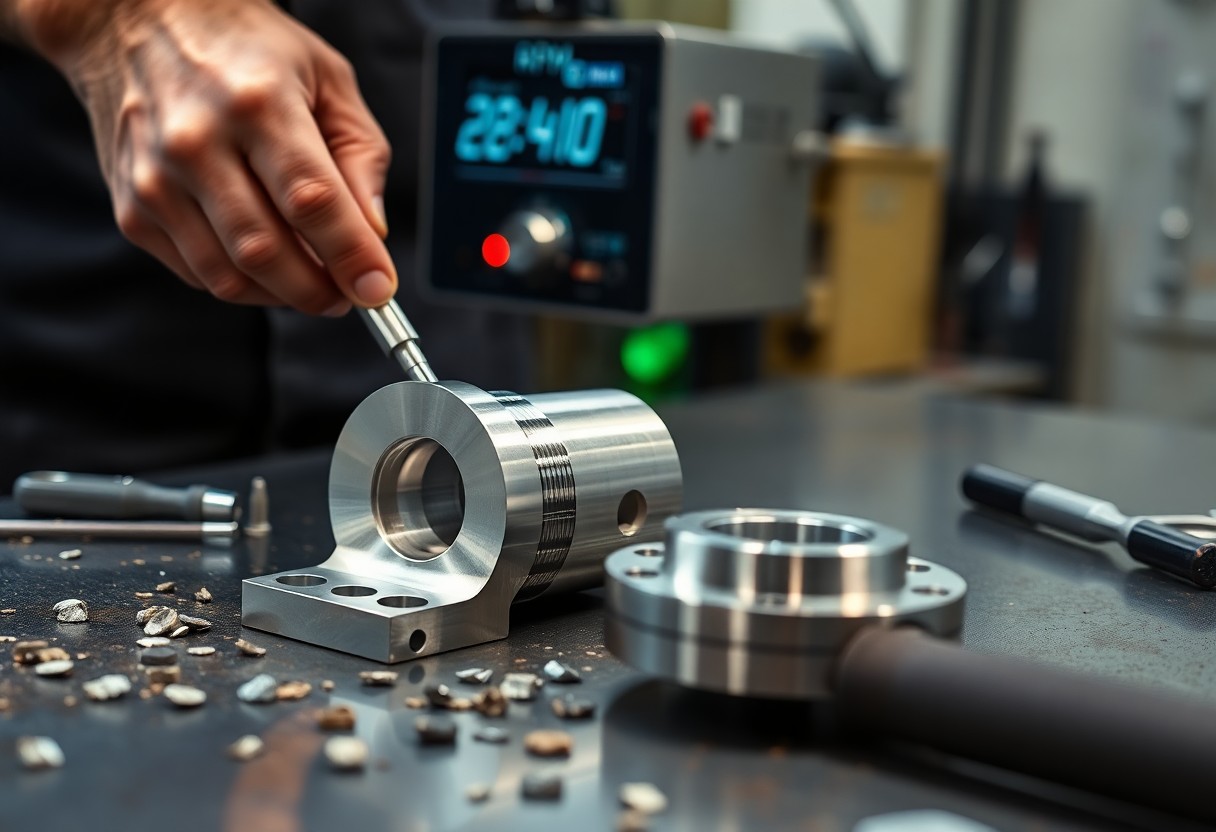

Most machinists face the challenge of selecting the right stainless steel for their projects, especially when comparing 410 and 316 grades. Understanding the differences in machinability between these two commonly used alloys can significantly impact your manufacturing processes and outcomes. In this post, you’ll gain insights into how their properties affect machining performance and what factors to consider to make an informed choice for your specific application.

Key Takeaways:

- 410 stainless steel offers better machinability compared to 316 due to its higher carbon content, which aids in cutting and shaping.

- 316 stainless steel is more resistant to corrosion, making it preferable for applications where durability is crucial, despite being harder to machine.

- Tooling and machining parameters need to be adjusted for 316 stainless steel to achieve desired outcomes, increasing production time and costs.

Overview of Stainless Steel Grades

When identifying stainless steel for machining, it’s crucial to understand the various grades available and their specific characteristics. Each grade is designed to meet different performance requirements; for example, grades like 410 and 316 are commonly used due to their unique compositions and properties. You’ll find that these grades differ significantly in corrosion resistance, hardness, and machinability, which ultimately impacts your machining processes and the longevity of the parts produced.

Properties of 410 Stainless Steel

410 stainless steel is known for its high strength and moderate corrosion resistance. It features a martensitic structure, providing excellent wear resistance and the ability to be hardened through heat treatment. This makes it ideal for applications requiring high wear resistance and moderate toughness. However, its hardness can pose challenges during machining, often requiring specialized tools to achieve desired results.

Properties of 316 Stainless Steel

In contrast, 316 stainless steel is recognized for its superior corrosion resistance, particularly in chlorinated environments. This austenitic grade contains molybdenum, enhancing its resistance to pitting in acidic conditions. Its ductility and formability make this grade more desirable for intricate designs and applications that demand high strength alongside corrosion resilience.

The nickel content in 316 stainless steel contributes to its excellent toughness even in extreme temperatures, making it suitable for a wide range of applications, including marine environments and chemical processing. In terms of machinability, 316 can be challenging due to its toughness, requiring higher cutting speeds or specialized tools. Yet, with proper techniques, you can achieve effective machining while maintaining surface integrity and dimensional accuracy.

Machinability Factors

Several factors affect the machinability of 410 and 316 stainless steels. These include the material’s composition, microstructure, and mechanical properties. When selecting machining parameters, consider the following:

- Impact of cutting speed

- Tool wear rates

- Chip formation and removal

- Fluid use for cooling

- Workpiece geometry

Any optimization in these areas can lead to enhanced performance during machining operations.

Hardness and Wear Resistance

410 stainless steel usually exhibits higher hardness than 316, making it more abrasive to tools and decreasing machinability. However, its hardness lends improved wear resistance, which is advantageous in specific applications. Conversely, 316 stainless steel possesses lower hardness with a more ductile structure, facilitating easier machining but less wear resistance. Understanding the trade-off between hardness and machinability is key when choosing the material for your project.

Tooling and Cutting Techniques

Selecting the right tooling and cutting techniques significantly impacts the ease of machining 410 and 316 stainless steels. High-speed steel (HSS) or carbide tools are often recommended for their robustness against wear. Additionally, utilize insert geometries that enhance chip evacuation and reduce friction. Notably, softer metals like 316 may benefit from higher cutting speeds, while 410 may require a more balanced approach to minimize tool degradation. Understanding the properties of your selected material will help you optimize your tooling choices.

Performance in Manufacturing

When evaluating the performance of 410 and 316 stainless steel in manufacturing, each grade exhibits distinct characteristics influencing production efficiency. 410 stainless steel, known for its hardness and wear resistance, is often preferred in applications requiring durable components. In contrast, 316 stainless steel excels in corrosion resistance, making it ideal for environments exposed to harsh chemicals or marine applications. Understanding these performance attributes allows you to choose the appropriate grade based on your specific manufacturing needs.

Applications of 410 Stainless Steel

410 stainless steel is commonly utilized in applications requiring high strength and moderate corrosion resistance. These include components such as knives, cutlery, valves, and pumps, where the material’s hardness contributes to longevity and performance in demanding environments.

Applications of 316 Stainless Steel

316 stainless steel is widely used in chemical processing, food and beverage applications, and marine environments due to its exceptional corrosion resistance. Its ability to withstand saltwater and acidic conditions makes it a popular choice for components like heat exchangers, storage tanks, and surgical instruments.

The versatility of 316 stainless steel extends beyond traditional applications as well. It’s often employed in the manufacture of pharmaceutical equipment, where cleanliness and corrosion resistance are critical. Additionally, in oil and gas industries, 316 stainless steel components are important for downhole equipment and pipelines, demonstrating its effectiveness in both standard and extreme conditions.

Cost Considerations

Pricing Differences

When comparing 410 and 316 stainless steel, the pricing often reflects their composition and corrosion resistance. Generally, 410 stainless steel is less expensive due to its lower nickel content, averaging around $2.00 to $4.00 per pound, whereas 316 stainless steel, which contains molybdenum and higher nickel levels, may range from $3.00 to $7.00 per pound. Your choice will depend on budget and application requirements.

Impact on Manufacturing Costs

Your choice between 410 and 316 stainless steel not only affects material costs but also influences overall manufacturing expenses. While 410’s lower initial price can be appealing, its relatively higher machinability may lead to reduced tool wear and lower machining times, offsetting the cost savings of using 316. Conversely, the durability and corrosion resistance of 316 can lead to less frequent repairs and replacements in demanding environments, potentially saving additional costs in the long run.

In applications where longevity and corrosion resistance are pivotal, opting for 316 stainless steel may save you substantial maintenance expenses and downtime. On the other hand, if your project is budget-sensitive and tolerates some corrosion risk, 410 steel could minimize upfront costs. Evaluating the total cost of ownership-including material price, machining expenses, and long-term performance-will guide you towards the most economical choice for your specific situation.

Comparison of Machinability

| 410 Stainless Steel | 316 Stainless Steel |

| Moderate machinability; good for some applications. | Superior machinability; preferred for complex components. |

| Better with high-speed steel tools. | Works well with carbide tools. |

| Prone to work hardening. | Less prone to work hardening. |

Ease of Machining 410 Stainless Steel

Machining 410 stainless steel presents moderate challenges due to its tendency to work harden. You’ll find that using high-speed steel tools can yield decent results, though tool wear may be an issue. It often requires slower cutting speeds and careful handling to prevent surface damage and maintain cutting efficiency.

Ease of Machining 316 Stainless Steel

When considering machining 316 stainless steel, you’ll notice its superior machinability relative to 410. Carbide tools perform effectively, allowing for faster cutting speeds and longer tool life. This alloy is more forgiving, enabling efficient machining with minimal issues related to tool wear.

316 stainless steel’s ease of machining can be attributed to its balanced composition, which includes molybdenum. This addition improves the material’s machinability, allowing you to achieve tighter tolerances and finer finishes. Users often report smoother operations, making it ideal for complex shapes and intricate designs in various applications.

Industry Preferences

Sectors Favoring 410 Stainless Steel

Your choice of 410 stainless steel often aligns with sectors requiring wear resistance and moderate corrosion resistance. Industries such as automotive manufacturing and tooling benefit from 410’s hardness. This grade is commonly utilized in applications like blades, fasteners, and kitchen utensils, where durability is vital without extensive exposure to corrosive environments.

Sectors Favoring 316 Stainless Steel

If your work involves marine applications or pharmaceutical environments, you’ll likely favor 316 stainless steel. Its superior corrosion resistance makes it ideal for situations with exposure to saltwater, acids, or harsh chemicals. Industries such as food processing, petrochemical, and wastewater treatment often rely on 316 due to its ability to withstand extreme conditions without compromising structural integrity.

The food processing industry particularly benefits from 316 stainless steel’s hygienic properties and ease of cleaning, as it prevents bacterial contamination during food handling. Similarly, in pharmaceutical applications, the non-reactive nature of 316 ensures that products are not compromised by the material itself. Its versatility also extends to the oil and gas sector, where equipment must endure corrosive fluids and harsh environments, making it a preferred material choice for valves, pumps, and tubing.

Conclusion

Now that you have reviewed the differences between 410 and 316 stainless steel, it’s clear that 410 offers better machinability due to its hardness and lower alloy content, making it easier for you to work with in various applications. In contrast, 316 provides enhanced corrosion resistance but can be more challenging to machine. Ultimately, the choice will depend on your specific project requirements and the trade-offs you are willing to make between machinability and other material properties.

FAQ

Q: What is the main difference in machinability between 410 and 316 stainless steel?

A: 410 stainless steel is generally easier to machine than 316 stainless steel. This is due to 410’s higher carbon content, which enhances hardness and wear resistance but also allows for better chip formation and removal during machining. In contrast, 316 has a lower carbon content and higher nickel and molybdenum levels, making it tougher and more ductile, which can make machining more challenging.

Q: How do cutting tools differ when machining 410 compared to 316 stainless steel?

A: When machining 410 stainless steel, cutting tools can be made from high-speed steel or carbide, as both perform well due to the material’s properties. For 316 stainless steel, carbide tools are typically preferred because they can withstand the material’s toughness and prevent tool wear caused by the higher nickel and molybdenum content. Consequently, the tool choice fluctuates based on the stainless steel type, affecting tooling costs and machining efficiency.

Q: What machining methods are most effective for 410 and 316 stainless steel?

A: For 410 stainless steel, methods such as turning and milling using high-speed steel or carbide tools at moderate speeds yield good results due to its chip-forming characteristics. In contrast, 316 stainless steel is best machined at lower speeds with constant coolant supply to avoid work hardening and tool wear, often requiring slower feed rates and specialized tooling to manage its toughness effectively.