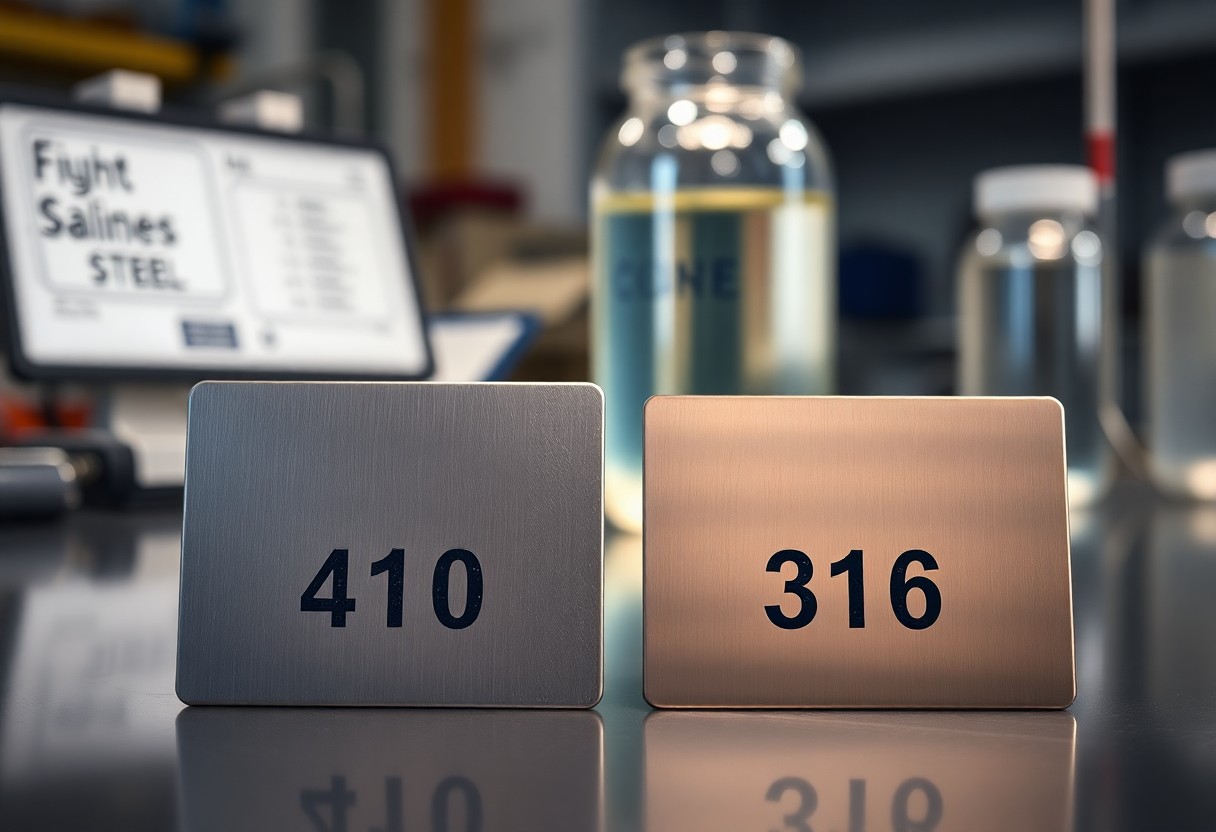

You may find yourself at a crossroads when selecting between 410 and 304 stainless steel for your projects. Understanding the differences in properties, applications, and corrosion resistance will help you make an informed choice that best suits your needs. While 410 offers enhanced hardness, 304 provides excellent corrosion resistance and formability. This guide will help you evaluate both grades, enabling you to select the most suitable option for durability and performance in your specific application.

Key Takeaways:

- Type 304 stainless steel offers superior corrosion resistance, making it ideal for food processing and chemical applications.

- Type 410 stainless steel is more suitable for applications requiring higher strength and hardness, especially in cutlery and industrial tools.

- Cost considerations may influence the choice, with 410 being generally less expensive than 304, but service requirements should guide the final decision.

Overview of Stainless Steel Grades

Stainless steel is categorized into various grades based on their composition and properties, each tailored for specific applications. The key distinctions among these grades primarily relate to their corrosion resistance, mechanical strength, and fabrication characteristics. Understanding these differences helps you make informed decisions when selecting the appropriate grade for your project.

Definition of 410 Stainless Steel

Type 410 stainless steel is a martensitic alloy containing approximately 11.5% chromium and is known for its moderate corrosion resistance and high strength. It can be heat-treated for enhanced hardness, making it suitable for applications like cutlery, industrial blades, and valve components.

Definition of 304 Stainless Steel

Type 304 stainless steel is an austenitic alloy composed of roughly 18% chromium and 8% nickel, providing excellent corrosion resistance and good weldability. This grade is commonly used in kitchen equipment, food processing, and other applications where hygiene is crucial.

Type 304’s composition gives it exceptional resistance to a wide range of chemicals and environments, making it the preferred choice in many industries. For example, its use in medical devices and food-grade applications underscores its versatility and reliability. Additionally, the 304 alloy’s ability to resist oxidation in high-temperature conditions further solidifies its reputation for durability, providing assurance in critical scenarios where performance is non-negotiable.

Chemical Composition

The chemical composition of stainless steel plays a significant role in determining its properties and applications. Both 410 and 304 grades have distinct compositions, which affect their performance, corrosion resistance, and suitability for various environments.

Key Elements in 410 Stainless Steel

410 stainless steel primarily consists of iron, chromium (11.5-13.5%), and a small amount of carbon (0.08% max). This composition provides a degree of hardness and moderate corrosion resistance, making it suitable for applications that require wear resistance.

Key Elements in 304 Stainless Steel

In contrast, 304 stainless steel has a higher content of chromium (18-20%) and nickel (8-10.5%), which contributes to its excellent corrosion resistance and formability. The addition of nickel enhances its ability to withstand harsh environments, making it a popular choice in food processing and chemical industries.

The higher nickel content not only improves corrosion resistance but also enables better workability in 304 stainless steel. This alloy resists oxidation and pitting in various environments, including acidic and alkaline conditions, making it ideal for high-stress scenarios. Its composition also allows for easy fabrication into various shapes and forms, adding to its versatility across multiple applications.

Mechanical Properties

The mechanical properties of stainless steel are vital for understanding how each grade performs under stress and strain. In this context, the hardness and strength of the material significantly influence its suitability for various applications, as these characteristics can determine durability, wear resistance, and performance in specific environments.

Hardness and Strength of 410 Stainless Steel

410 stainless steel boasts a higher hardness and strength compared to 304, particularly after heat treatment. With a Rockwell Hardness scale rating typically around 45 HRC, this martensitic stainless steel is designed for applications requiring exceptional wear resistance and structural integrity, such as in cutlery and surgical instruments.

Hardness and Strength of 304 Stainless Steel

In contrast, 304 stainless steel provides a balance of adequate strength and ductility, with a Rockwell Hardness around 70 HRB. While it may not match the hardness of 410, its solid tensile strength allows for effective applications in processing plants and architectural fixtures, where corrosion resistance is prioritized over extreme hardness.

304 stainless steel’s ductility is vital when considering forming and welding applications. For example, its ability to withstand significant deformation without fracturing makes it ideal for creating complex shapes in food processing equipment. The combination of moderate strength and excellent corrosion resistance allows 304 to excel in environments where hygiene and durability are paramount, such as in dairy processing and chemical handling.

Corrosion Resistance

Corrosion resistance is a critical factor when choosing between 410 and 304 stainless steel, as it directly impacts the longevity and performance of your application.

410 Stainless Steel Corrosion Resistance

410 stainless steel offers moderate corrosion resistance, which is adequate for environments with low to moderate exposure to humidity and some chemicals. However, its resistance pales compared to other grades like 304, especially in salty or acidic conditions, making it less ideal for stringent applications.

304 Stainless Steel Corrosion Resistance

In contrast, 304 stainless steel exhibits exceptional corrosion resistance due to its higher chromium and nickel content. This makes it suitable for a wide range of environments, including marine applications and food processing, as it can resist rust and pitting effectively.

With a composition that typically includes around 18% chromium and 8% nickel, 304 stainless steel withstands corrosive elements like chlorides and acidic compounds, allowing for prolonged use without degradation. For instance, in coastal areas, structures made from 304 are favored because they maintain their integrity despite exposure to saline conditions, ensuring both safety and durability in various applications.

Applications and Use Cases

Each stainless steel grade has its unique set of applications based on its properties. Understanding where to deploy 410 and 304 stainless steel will enhance your projects’ durability and performance. Evaluating specific use cases helps you make informed decisions tailored to your needs.

Common Applications of 410 Stainless Steel

410 stainless steel is widely used in applications requiring good wear resistance and moderate corrosion resistance. You’ll find it in manufacturing cutlery, tools, and kitchen utensils, as well as components in industrial equipment and machinery where friction is a factor.

Common Applications of 304 Stainless Steel

304 stainless steel is renowned for its versatility and corrosion resistance, making it suitable for a broad range of applications. Typically, you’ll see it in food processing environments, kitchen appliances, and architectural structures. It’s also common in chemical containers and pharmaceutical equipment due to its hygienic properties.

304 stainless steel’s adaptability explains its popularity in various industries. For instance, in the food industry, its resistance to oxidation and ease of cleaning make it an ideal choice for equipment like mixers, tanks, and conveyor belts. Additionally, its aesthetic appeal makes it a preferred material for countertops and railings in public spaces, enhancing both functionality and design.

Cost Considerations

When evaluating your options between 410 and 304 stainless steel, cost considerations play a significant role. The pricing for these grades can fluctuate based on market demand, availability, and geographical location. In general, 410 tends to be less expensive due to its lower nickel content, making it a favorable choice for budget-conscious projects without compromising too much on quality.

Pricing Trends for 410 Stainless Steel

410 stainless steel typically shows a price range that is lower than 304, often about 10-20% cheaper. This lower price point can be attributed to its simpler composition, which contains less nickel. Market conditions can impact these prices, but 410 remains an economical choice for various applications.

Pricing Trends for 304 Stainless Steel

304 stainless steel generally commands a higher price, largely due to its increased nickel content, which imparts enhanced corrosion resistance and durability. Pricing for this grade can vary significantly, particularly in response to fluctuations in nickel prices. Over the past year, you may have noticed an average price increase of around 5-15%, reflecting ongoing supply chain challenges.

In recent industry reports, the price of 304 stainless steel has been influenced by global demand and industrial usage. As manufacturers invest in higher quality materials, 304 continues to rise in popularity in sectors such as food processing and construction, further driving costs. Depending on the supplier and region, expect variations in pricing, but overall trends lean towards a stable increase due to consistent demand for its superior properties.

Summing up

To wrap up, when choosing between 410 and 304 stainless steel, consider your specific needs such as corrosion resistance, strength, and application environment. If you require higher corrosion resistance, 304 is your best option, while 410 offers improved hardness and wear resistance for cutting tools and high-stress applications. Evaluating these characteristics against your project requirements will guide you to the most suitable grade for your purposes.

FAQ

Q: What are the main differences between 410 and 304 stainless steel?

A: The primary differences between 410 and 304 stainless steel include their composition and properties. 410 is a martensitic stainless steel that offers higher hardness and wear resistance, making it suitable for cutting tools and blades. In contrast, 304 is an austenitic stainless steel known for its excellent corrosion resistance and formability, ideal for kitchen equipment and food processing.

Q: Which stainless steel grade is better for outdoor applications?

A: For outdoor applications, 304 stainless steel is generally the better choice due to its superior corrosion resistance in harsh environments, including exposure to moisture and various chemicals. 410 stainless steel, while durable, is more susceptible to rust and requires protective coatings or regular maintenance when used outdoors.

Q: How do the costs compare between 410 and 304 stainless steel?

A: Usually, 410 stainless steel is less expensive compared to 304 stainless steel. The cost difference arises from the variations in alloying elements and manufacturing processes. However, the total cost should also consider the specific application requirements and potential long-term maintenance expenses.