Understanding Acamento

The term Acamento refers to the process, art, and science of finishing surfaces to achieve a desired aesthetic, functional, or tactile quality. Originating from the Latin root “acamen,” meaning refinement or completion, Acamento goes beyond simple polishing it embodies precision, artistry, and purpose. Whether it’s the gleaming surface of a metal sculpture, the satin texture of furniture, or the smooth finish of architectural interiors, Acamento defines the final identity of a product.

It involves the interaction of tools, materials, and techniques designed to enhance both appearance and durability. From industrial factories to artisan workshops, Acamento bridges engineering with design, uniting form and function through surface excellence.

Importance of Acamento in Various Industries

Acamento plays a crucial role across multiple industries, each demanding specific finishes that affect performance, longevity, and visual impact.

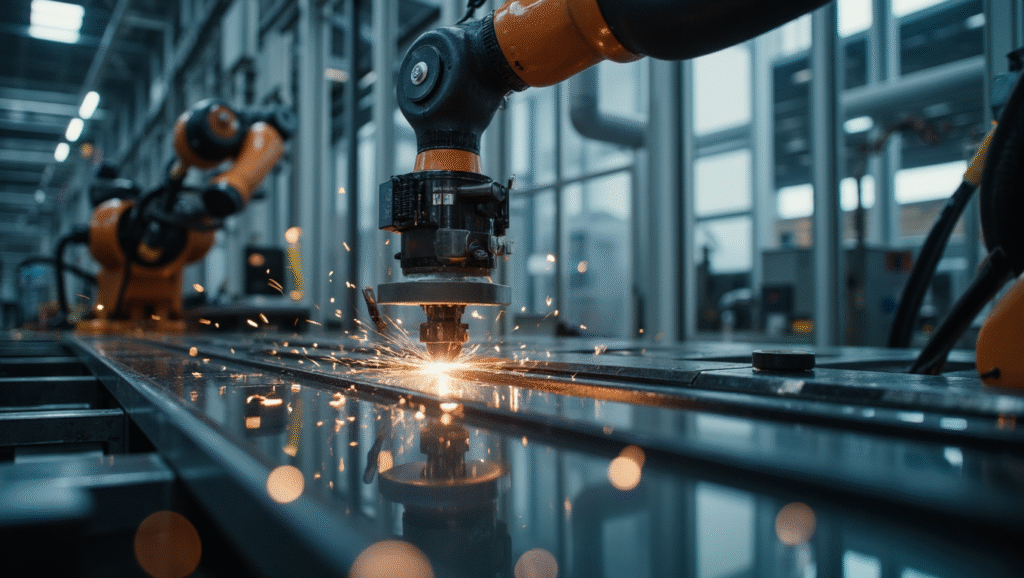

In Manufacturing:

The manufacturing sector uses Acamento to refine metals, plastics, and ceramics. A well-finished surface improves corrosion resistance, reduces friction, and ensures precise assembly. For example, automotive components rely on Acamento to enhance aerodynamic flow and visual appeal.

In Architecture and Construction:

Architects view Acamento as an essential phase of design realization. It determines how light interacts with surfaces, how textures feel under touch, and how colors harmonize in a space. Wall coatings, concrete polishing, and metallic laminates all rely on controlled finishing processes.

In Interior Design and Furniture:

From glossy marble countertops to matte wooden cabinets, interior designers use Acamento to set the tone of a space. The finish affects ambiance, functionality, and even acoustics. Matte finishes create calm environments, while high-gloss surfaces reflect light for a vibrant atmosphere.

In Fine Art and Jewelry:

Artists and jewelers have used Acamento for centuries to evoke emotion through sheen, texture, and contrast. The final polish determines the artwork’s soul — reflective for boldness or muted for elegance.

Types of Acamento Finishes and Material Compatibility

Different materials respond uniquely to Acamento techniques. Understanding compatibility ensures long-term stability and aesthetics.

Polished Finish:

Achieved through mechanical abrasion or chemical treatment, polished finishes offer a mirror-like shine. Metals such as stainless steel and brass exhibit high reflectivity and corrosion resistance after polishing.

Brushed or Satin Finish:

Brushed Acamento creates a soft texture with visible linear patterns. It’s commonly used in appliances, architectural metal panels, and furniture for a contemporary look.

Matte and Etched Finishes:

For subtlety, matte finishes diffuse light and hide imperfections. Etching involves mild abrasion or acid exposure, adding depth to materials like glass, ceramics, and aluminum.

Coated or Painted Acamento:

Protective coatings, including powder coating, lacquer, and nanofilm applications, combine beauty with durability. These layers prevent oxidation and allow creative color experimentation.

Natural Stone and Wood Acamento:

Stone and wood require specialized treatments — sanding, sealing and oiling — to highlight grain and texture. Their organic patterns respond beautifully to careful craftsmanship.

Application of Acamento Techniques

Acamento techniques vary according to the desired outcome and the nature of the surface.

Mechanical Techniques:

Processes such as grinding, buffing, and sanding remove irregularities, refine edges, and produce smoothness. These are essential in precision manufacturing and furniture design.

Chemical Techniques:

Acids, alkalis, or specialized solutions are applied to alter the chemical structure of the surface. This helps in achieving corrosion resistance and decorative effects, especially on metals and glass.

Thermal and Electrochemical Techniques:

Electropolishing and heat treatments enhance reflectivity, hardness, and texture consistency. Used in medical equipment and aerospace industries, these methods ensure both hygiene and high performance.

Artisan and Hybrid Techniques:

In luxury interiors or handcrafted art, Acamento involves hand-rubbing, layering, or mixed-media polishing. These hybrid methods combine machine precision with artistic intuition.

Mastering Acamento: Tools, Materials and Techniques

To achieve mastery in Acamento, understanding the synergy between tools and materials is essential.

Essential Tools:

Abrasive wheels and sandpapers

Buffing machines and polishing pads

Spray systems for coatings

Ultrasonic cleaners for delicate materials

Key Materials:

Metals: Stainless steel, aluminum, brass

Non-metals: Ceramics, glass, composites

Natural elements: Wood, stone, clay

Advanced Techniques:

Modern Acamento integrates digital control systems, enabling micro-precision. CNC finishing, laser texturing, and robotic polishers are redefining craftsmanship in high-end industries.

Incorporating Acamento in Home Decor and Projects

Acamento is increasingly popular in DIY home improvement and interior customization.

Wall and Surface Design:

Polished plaster, metallic wall coatings, and matte cement textures create depth and sophistication in homes.

Furniture Restoration:

Old furniture gains new life through sanding, varnishing, and layering — the essence of domestic Acamento.

Decorative Accents:

Mirror-polished metals, stone tabletops, and resin finishes elevate everyday objects into art pieces. The tactile quality of finishes influences comfort and mood in living spaces.

Troubleshooting and Maintenance

A well-executed Acamento demands periodic care to retain its visual and functional qualities.

Common Issues:

Surface dulling due to oxidation

Scratches from improper cleaning tools

Fading of coatings under UV exposure

Maintenance Tips:

Use pH-neutral cleaning agents

Avoid abrasive cloths on glossy surfaces

Reapply sealants for porous materials every 6–12 months

Proper maintenance extends the lifespan of Acamento-treated materials and keeps them looking pristine.

Comparing Acamento Across Industries

Automotive Industry:

Focuses on anti-corrosive coatings and aerodynamic polish. Chrome plating and ceramic coatings enhance durability.

Construction and Architecture:

Emphasizes tactile and visual harmony using Acamento for concrete polishing, terrazzo surfaces, and sustainable facade materials.

Consumer Electronics:

Smartphones and laptops rely on precise micro-finish technology for tactile smoothness and minimal reflectivity.

Aerospace and Medical Fields:

Demand sterile, highly polished finishes to reduce contamination and enhance performance.

Acamento in Historical, Cultural and Psychological Context

Historically, Acamento symbolized craftsmanship and spiritual connection. Ancient artisans believed a perfectly finished object reflected inner purity. Egyptian tomb relics, Japanese lacquerware, and Renaissance sculptures all share this philosophy.

Culturally, Acamento represents attention to detail a metaphor for discipline and excellence. Psychologically, smooth surfaces evoke calm and satisfaction, while textured finishes stimulate curiosity and engagement.

Today, this philosophy endures. The way we finish our surroundings mirrors how we value perfection and harmony in life.

Future Trends and Innovations in Acamento

As technology and sustainability converge, Acamento evolves beyond traditional limits.

Smart Surface Technology:

Nanocoatings and self-healing films respond to scratches or dirt autonomously, maintaining flawless finishes without intervention.

Eco-friendly Acamento:

Green materials and low-VOC finishes are revolutionizing interior design and industrial manufacturing. Water-based solutions and recycled abrasives reduce environmental impact.

Digital and AI Integration:

AI-driven systems predict wear patterns and automate finishing precision. Digital modeling allows designers to preview how different Acamento styles will appear before production.

Hybrid Textures:

Combining matte and glossy zones creates dynamic visuals — a trend seen in automotive design and luxury interiors alike.

Case Studies and Practical Application

Case Study 1 – Automotive Finishing Excellence:

A European car manufacturer implemented a dual-layer Acamento technique using ceramic and graphene coatings. The result was improved reflectivity, reduced drag, and 30% longer paint durability.

Case Study 2 – Sustainable Architecture Project:

An eco-hotel in Bali adopted natural lime Acamento for interior walls, balancing breathability and aesthetic warmth. This reduced carbon emissions by 25% compared to synthetic coatings.

Case Study 3 – Artisanal Metalworks:

A small studio in Portugal revived traditional copper polishing using hybrid mechanical-acid methods, achieving mirror finishes while preserving cultural heritage.

Symbolism and Benefits of Acamento

Acamento symbolizes refinement, transformation, and the pursuit of perfection. Its benefits extend beyond beauty it improves durability, enhances ergonomics, and communicates value.

In homes, it inspires comfort and calm. In industries, it drives efficiency and precision. In culture, it preserves identity through artistry.

Every surface tells a story Acamento ensures that story is one of mastery, resilience, and creativity.

Conclusion

Acamento is more than finishing it’s a philosophy of refinement woven through human history. From ancient artisans to modern engineers, the goal remains the same: to bring raw materials to their highest potential. Whether shaping architecture, enhancing machinery, or crafting personal spaces, Acamento defines the transition from functionality to artistry.

Its evolution mirrors humanity’s endless quest for perfection blending sustainability, innovation, and design into one transformative practice.

FAQs

Q1. What is Acamento used for?

Acamento refers to surface finishing techniques used across industries to enhance texture, appearance, and durability.

Q2. Is Acamento limited to industrial applications?

No. It applies equally to art, interior design, and architecture, offering both aesthetic and practical benefits.

Q3. Which materials are most compatible with Acamento?

Metals, woods, ceramics, stones, and composites are commonly treated depending on the desired finish.

Q4. What are the latest trends in Acamento?

AI-assisted polishing, sustainable coatings, and hybrid finishes are shaping the modern future of surface design.

Q5. How can Acamento improve sustainability?

By using water-based coatings, recycled abrasives, and energy-efficient systems, Acamento supports eco-friendly manufacturing.